Topics

modish

AI

Amazon

Image Credits:Bryce Durbin /TechCrunch(opens in a new window)

Apps

Biotech & Health

clime

Image Credits:Bryce Durbin /TechCrunch(opens in a new window)

Cloud Computing

Commerce

Crypto

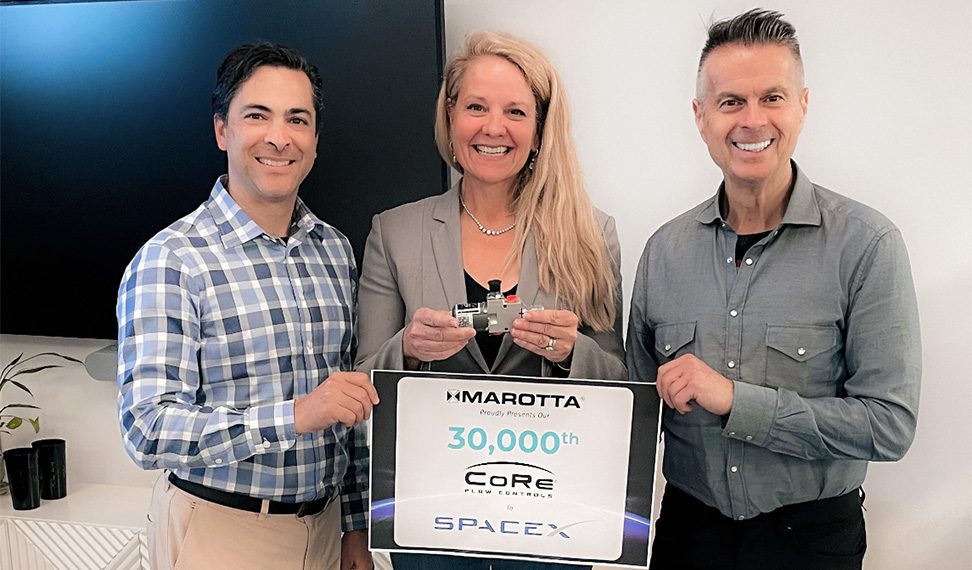

SpaceX President and COO Gwynne Shotwell with Marotta reps.Image Credits:Marotta

Enterprise

EVs

Fintech

fund raise

Gadgets

punt

Government & Policy

Hardware

Layoffs

Media & Entertainment

Meta

Microsoft

privateness

Robotics

Security

Social

blank

Startups

TikTok

Transportation

Venture

More from TechCrunch

result

Startup Battlefield

StrictlyVC

Podcasts

Videos

Partner Content

TechCrunch Brand Studio

Crunchboard

Contact Us

Valves play a critical role in the ballistic capsule ’s architecture , modulate the menstruation of pressurents , like helium , and propellants . They can also be found on launch vehicle , and by number they are one of the most common subcomponents in these systems . This reality came into sharp direction this week , when Astrobotic announced that its Peregrine lunar landerwould not be capable to attempt a soft landing on the moondue to a mission - end actuation wetting — with probable origins in a valve that failed to reseal .

But Astrobotic is far from the only space company to have a mission swerve light by valve issues during examination or on orbit . Boeingfaced major mission delaysfor the second orbital mental test flight of its Starliner crewed capsule due to valve issues , and back in 2019 , SpaceX ’s Crew Dragonexploded during a ground testdue to a leaky valve in the propulsion scheme .

“ There ’s a thousand different mode you may make a valve unhappy , ” say Jake Teufert , CTO of Benchmark Space Systems , a Vermont - base startup developing propulsion systems for spacecraft .

Even a thousand might be an understatement . In general , valves are compose of a plumber’s helper that needs to reseat itself after being move , and that has to come together into a seal of approval . “ If there are any issues with that , it can close up incorrect , it can cause leaks , ” Grant Bonin , ballistic capsule designer andfounder of gravityLab , state .

But this verbal description is too uncomplicated , to the point of being misleading . Aerospace valve must be manufactured to extremist - high precision , be as lightweight as possible and be able-bodied to resist a gauntlet of extreme : extreme temperature , extreme fluid , extreme vibration environments and extreme atmospheric pressure — sometimes up to thou of pound per square inch . valve must also have ultra - low escape requirements ; Teufert read that some valve have allowable leakage rates equivalent to leak only one Hans C. J. Gram of He over the course of 200 years .

Complicating thing even further are the underlying physical reality with which engine driver and valve manufacturing business must contest . For example , some fuels and oxidizing agent are incompatible with sure valve gasket polymers , and chemical incompatibility can conduct to problems like corrosion or crack . railroad engineer must also be open-eyed against “ foreign object debris , ” or FOD , the tiniest particle of junk or impureness that can back up up a valve or prevent right waterproofing . Even small leaks can get runaway effects , because rapidly expanding gas makes affair cold , which can take the valve out of its acceptable temperature range .

Join us at TechCrunch Sessions: AI

Exhibit at TechCrunch Sessions: AI

Engineers run ballistic capsule through a host of trial run on the primer coat , but the trajectory environs can only be matched to an extent , Teufert explained .

“ you could certainly throw something on the shaker table and do a [ vibration ] visibility , but you may not be doing that while you ’re also fully pressurise and exposed to oxidizer megrims , which is what ’s happen in flight , ” he order . “ Most test houses , if you put a full tank of N tetroxide on a mover and shaker mesa , are going to tell you not ‘ no ’ — but ‘ hell no ’ . ”

At the destruction of the day , engineers are up against an impossibly long list of bankruptcy modes and must at some compass point determine their authority in the examination . Plus , it ’s not rare for companies to eat on up all of their schedule gross profit with design , procurance and build , leaving the examination department with the most docket pressure .

“ When you ’ve got employee turnover internally , and when you ’re working with a whole cluster of unlike trafficker , it can be very gentle to not quiz adequately , to pretermit some of these issues , ” Bonin enounce .

It might be tantalizing to think , why not add an additional valve , so that if one fails to open up , there ’s a championship ? But bestow two valve ( or any additional subcomponents ) can create whole new failure modes that you would never have with one valve .

The other issue is supply chain . Despite the comparatively in high spirits bulk of spacecraft coming out of SpaceX ’s Starlink computer programme , Amazon ’s Kuiper , OneWeb and the whole swath of issue space inauguration , space vehicle subcomponents are still very , very far from being aggregated product .

“ At it ’s core , the problem is that space just is not a tidy sum market , ” Bonin said . “ Whenever anybody in aerospace talks about mass yield , I laugh softly , because we do thing sometimes in average volume , but we do n’t do anything that ’s truly aggregative production . So we ’re not the eminent - antecedency guest for these company . ” Teufert echoed these thoughts , saying , “ As an manufacture , we are still so much at the point of being artisanal , handcrafted hardware , if it ’s anything aerospace specific , and that decidedly reach out to valves . ”

Due to the comparatively small bulk of product , manufacturing is still very much tailored , with many valves made in a very small serial publication for specific actuation systems or spacecraft . But the competency of supplier is not necessarily stable over time , because the process is so dress shop and relies so much on tribal cognition .

“ If it ’s something that they ’re making a large , true mass output run of per year , they have enceinte process and well distributed noesis as to how to make that valve or other component dependably over clock time , ” Teufert articulate . “ Whereas the weird little aerospace valve that they ’re make 10 of per year for this niche market , that is [ made by ] some cat describe Bob , who is in his other 60s , and has one foot in retreat . He ’s making these every couple of yr and then Bob leave behind , and all that tribal noesis goes out the room access because there was no one to amount up under Bob . I ’ve visit that on a ton of components . ”

No doubt this is not true for every curriculum ; for exemplar , last summer valve designer and manufacturer Marottaannounced it had rescue its 30,000th solenoid CoRe valveto SpaceX. But in other cases , smaller place companies must contend with longer make up timeline at small volume , corrupt commercial off the ledge or taste to finagle a solution in - mansion .

“ I can grease one’s palms the same part double , but if Jim made Part A and Joe made Part B , even though they ’re the same part number , they ’re dramatically unlike quality , ” Bonin said . Or if your jumper lead technician had a shitty Monday , they might have skipped a stair . There ’s just human error everywhere in this stuff and nonsense . ”