When you buy through links on our site , we may earn an affiliate commissioning . Here ’s how it works .

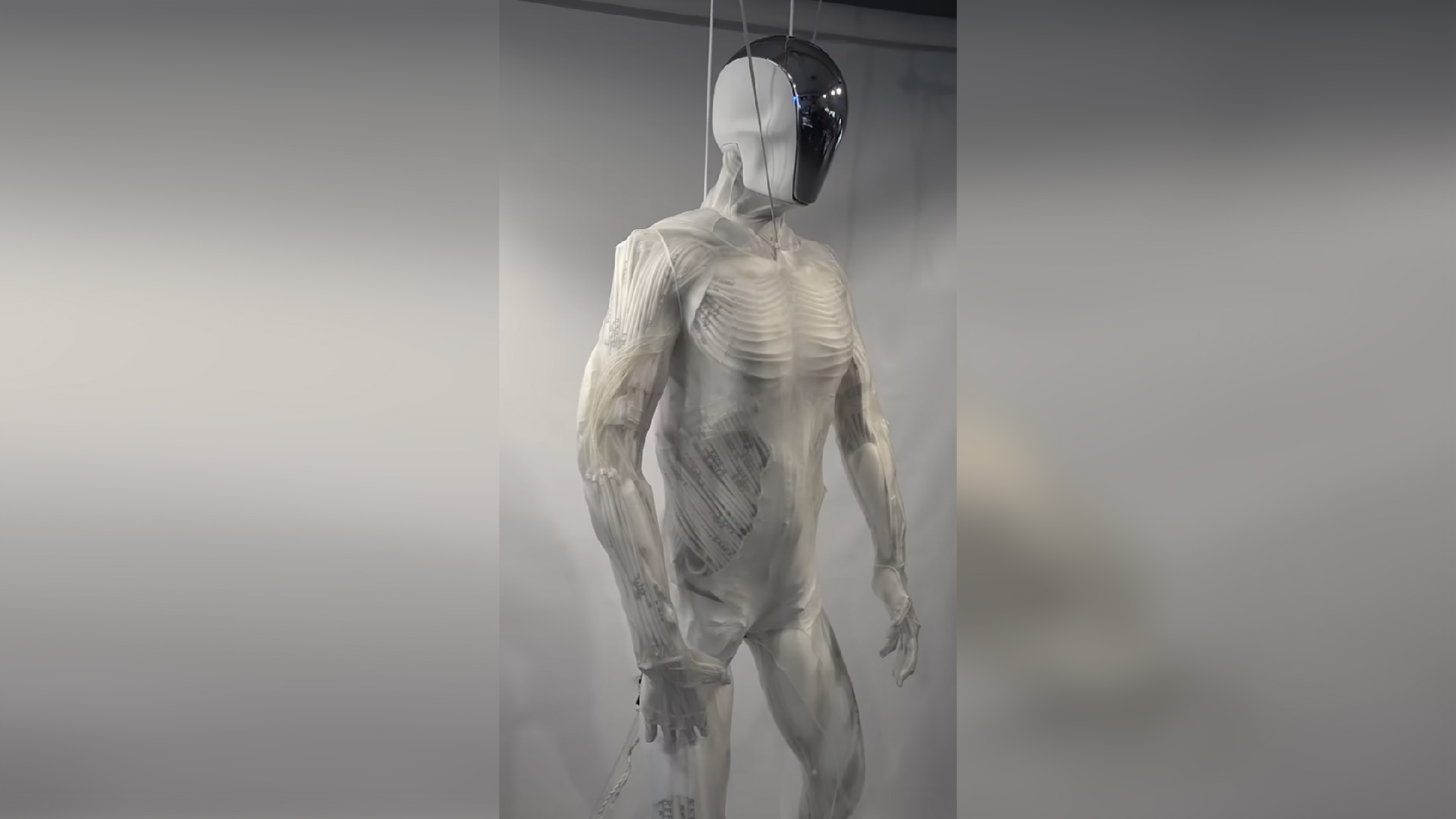

Scientists have produce the most human - like robotic hand ever , consummate with 3D - print bone , ligaments and sinew .

The breakthrough — the 3D printing of a mixture of hard and balmy parts by cross - layer up to four plastics — could be used to create more complex and durable robots , accord to the researchers who developed it .

An image montage of the soft robotic hand holding a marker pen and a water bottle.

The result is a firm but flaccid automatonlike part that can scale , unlike other soft golem that shinny to assert their physical properties at larger sizes , according to their determination published Nov. 15 in the journalNature .

The proficiency , known as vision - see to it jetting ( VCJ ) , probably wo n’t be used to create the biography - like Androids we know from shows like " West World " anytime presently . But they could make automated industries much safer .

relate : Tiny , shape - shifting golem could one solar day be used to do surgery from inside the organic structure

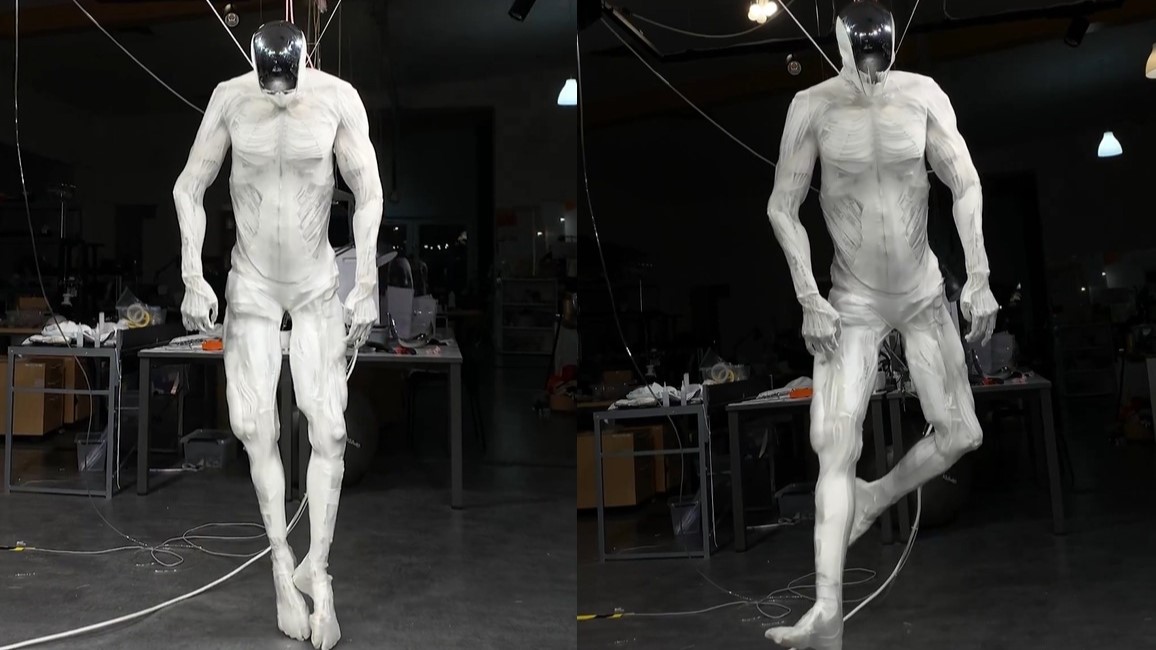

" Robots made of diffused materials , such as the hand we modernize , have advantages over conventional automaton made of metal , " first authorRobert Katzschmann , a prof of robotics at ETH Zurich , said in a statement . " Because they ’re gentle , there is less risk of injury when they ferment with humans , and they are well suitable to handle fragile goods . "

Although the robots that work alongside human beings in factoriesmalfunction seldom , they can be deadly when they do . On Nov. 8 , a South Korean man was crushed to last on a conveyor whang when an industrial robotmistook him for a loge of bell peppers .

— actual - living ' Terminator 2 ' robot can run to escape jail , then solidify on command

— Human - like robot tricks masses into thinking it has a brain of its own

— Pac - human being - shaped blob become world ’s first self - replicating biological robots

Robots today are also inflexible and miss the intricate internal structures call for to do complex movements and undertaking human race can well do , concord to the researcher . Many , such as metal implants , are ill - befit for use in aesculapian contexts too — causing fervour when human bodies detect a differencebetween their rigourousness and that of the surround tissue paper .

To lick this problem , the scientists define about three-D printing a range of devices ( include a six - legged robot , a running heart ticker and a fabric that absorbs vibrations from its surroundings ) that mime the complexness of nature ’s biomechanics .

To do so , they develop a way to 3D print slow - cure plastics . Unlike fast - bring around polyacrylates used in traditional 3D printing process , VCJ gives each bed of the machinelike part more time to set — resulting in a more perdurable and elastic printed component . tv camera and lasers point the pressman so that each bed is built up with the right thickness .

" We would n’t have been able to make this hand with the tight - cure polyacrylates we ’ve been using in 3D printing so far,“Thomas Buchner , a doctorial scholar at ETH Zurich , said in the statement . " We ’re now using slow - curing thiolene polymers . These have very estimable pliant properties and yield to their original state much faster after bending than polyacrylates [ the standard polymers used in 3D printing ] . ”