When you purchase through links on our site , we may take in an affiliate commissioning . Here ’s how it works .

Scientists have usedartificial intelligence(AI ) to project never - before - consider nanomaterials with the military strength of carbon sword and the lightness of styrofoam .

The Modern nanomaterials , made using simple machine learning and a 3D printer , more than doubled the metier of survive pattern . The scientists behind the new study said they could be used in stronger , lighter and more fuel - efficient components for plane and railcar . They put out their finding Jan. 23 in the journalAdvanced Materials .

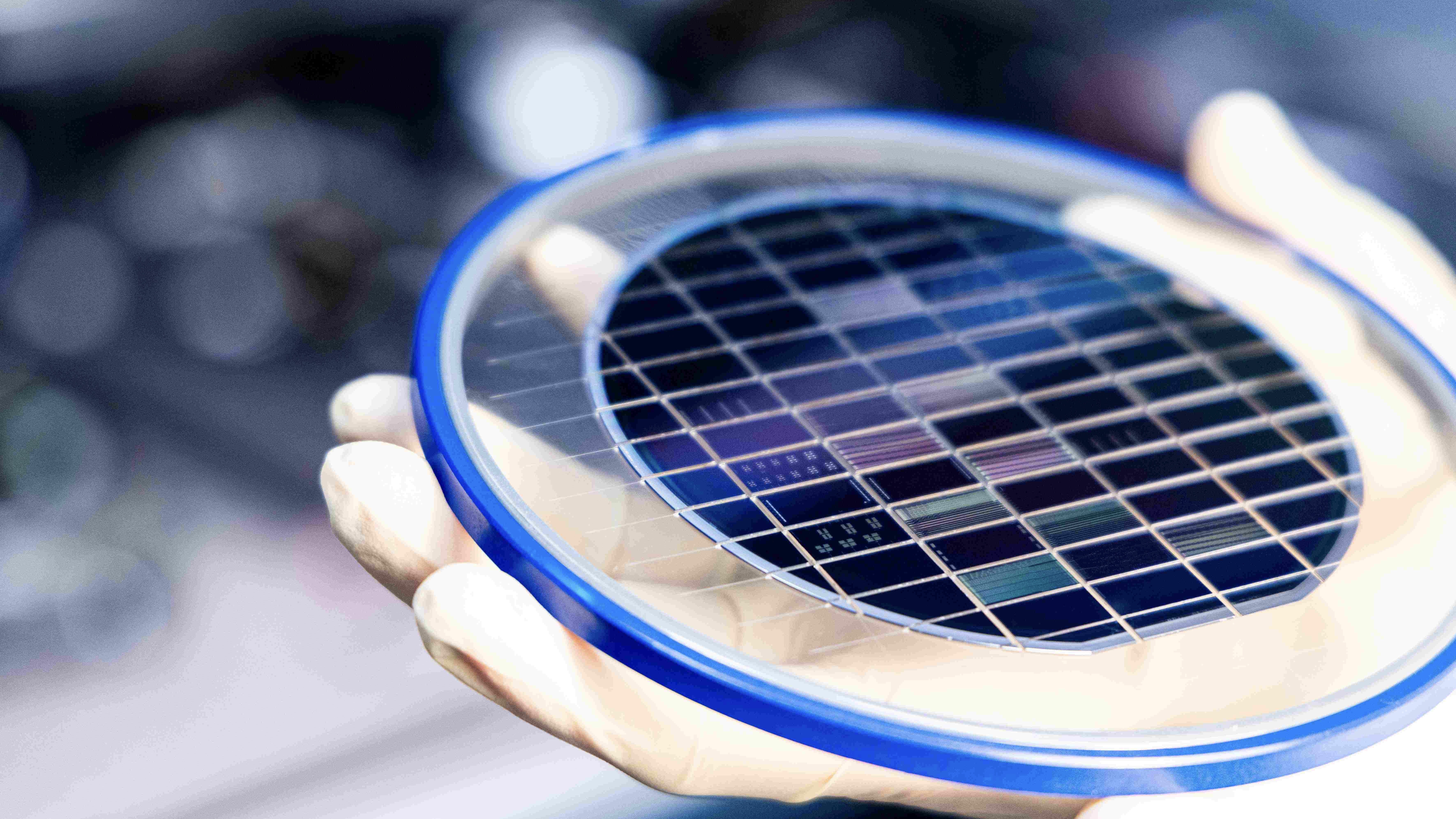

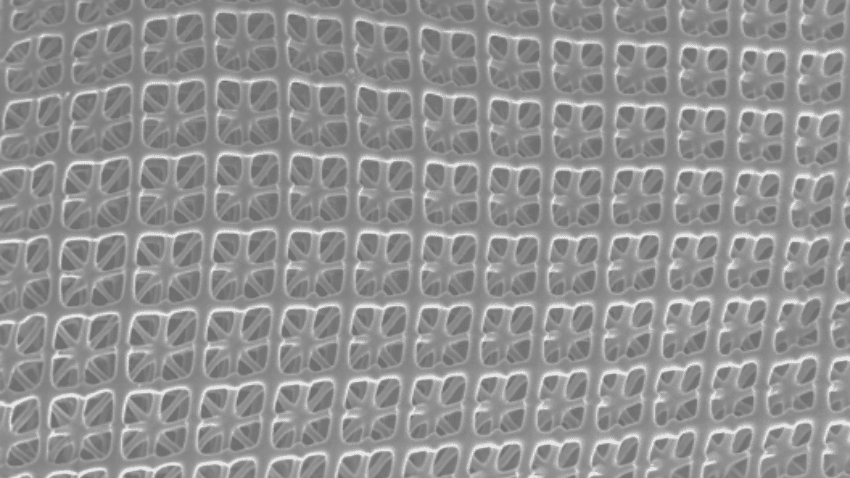

An image of the new nanomaterial.

" We hope that these new material design will finally run to ultra - light weight unit constituent in aerospace applications , such as plane , helicopters and ballistic capsule that can reduce fuel demands during flying while maintaining safety and performance , " co - authorTobin Filleter , a professor of engineering at the University of Toronto , said in a argument . " This can at last help abridge the gamey carbon step of flying . "

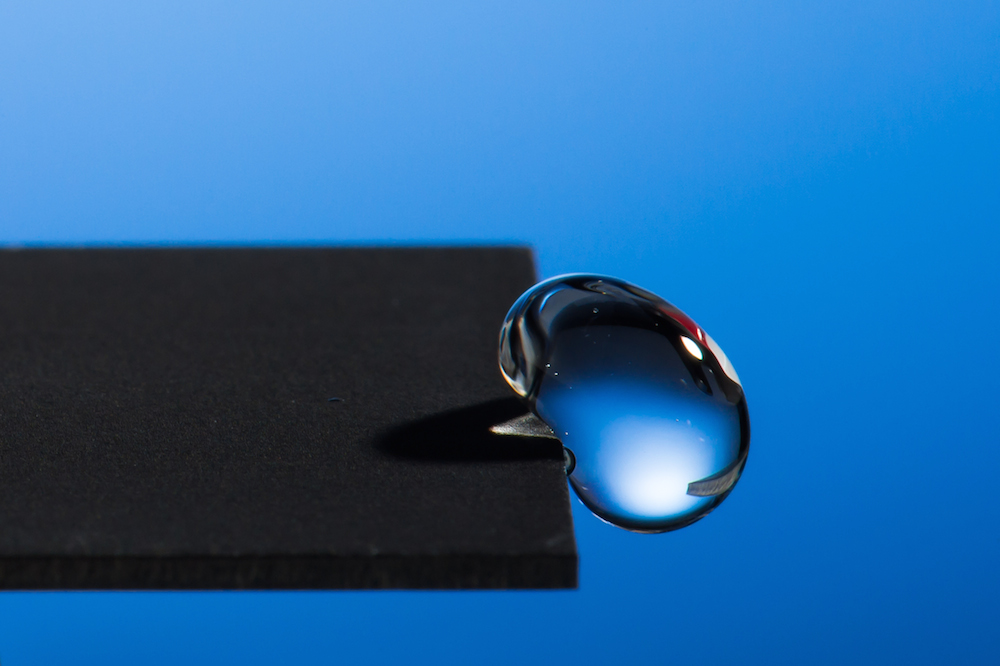

In many materials , posture and toughness can often be at betting odds . Take a ceramic dinner plate , for example : while plates are usually hard and can stock heavy stacks , their strength come at the cost of toughness — it does n’t take much vim to make them shatter .

Related : Scientists name revolutionary method that reach fuel from water and sunlight — but it ’s not finished yet

The same trouble applies to nano - architectured material , whose building from concourse of tiny , repeat building blocks 1/100th the thickness of a human hair makes them strong and stiff for their weight , but can also cause stress concentrations that lead to sudden breakages . So far , this tendency to shatter has limited the fabric ' applications .

" As I thought about this challenge , I realized that it is a unadulterated problem for machine eruditeness to undertake , " first - authorPeter Serles , an technology researcher at Caltech , enjoin in the statement .

To research for better ways to plan nanomaterials , the researchers simulated possible geometries for their design before passing them through a simple machine learning algorithm . By learn from the design they had generate , the algorithm was able to predict the best bod that would equally dole out applied focus while also carrying a heavy load .

— Inside the 20 - year quest to ravel the eccentric kingdom of ' quantum superchemistry '

— Scientists just get 1 step nigher to create a ' superheavy ' constituent that is so big , it will tote up a Modern row to the periodic board

— pill pusher broke a 100 - year - old convention to make extremely unstable molecules

With these pattern in hand , the researchers used a 3D printing machine to create their new nanolattices , finding that they could stand firm a stress of 2.03 megapascals for every cubic cadence per kilogram — a strength five time higher than titanium .

" This is the first time machine learning has been put on to optimise nano - architected materials , and we were shock by the improvement , " Serles allege . " It did n’t just replicate successful geometries from the training datum ; it learned from what changes to the embodiment worked and what did n’t , enable it to foretell whole novel wicket geometry . "

The researchers say their next footmark will center on scaling up the materials until they can be used to make bountiful components , while also searching for even good designs using their outgrowth . The primary intention is to design much light and stronger components for vehicles in the future .

" For instance , if you were to put back components made of titanium on a plane with this material , you would be looking at fuel savings of 80 litres per twelvemonth for every kilo of textile you replace , " Serles sound out .

You must confirm your public display name before commenting

Please logout and then login again , you will then be prompted to insert your presentation name .