When you purchase through links on our site , we may earn an affiliate delegacy . Here ’s how it act .

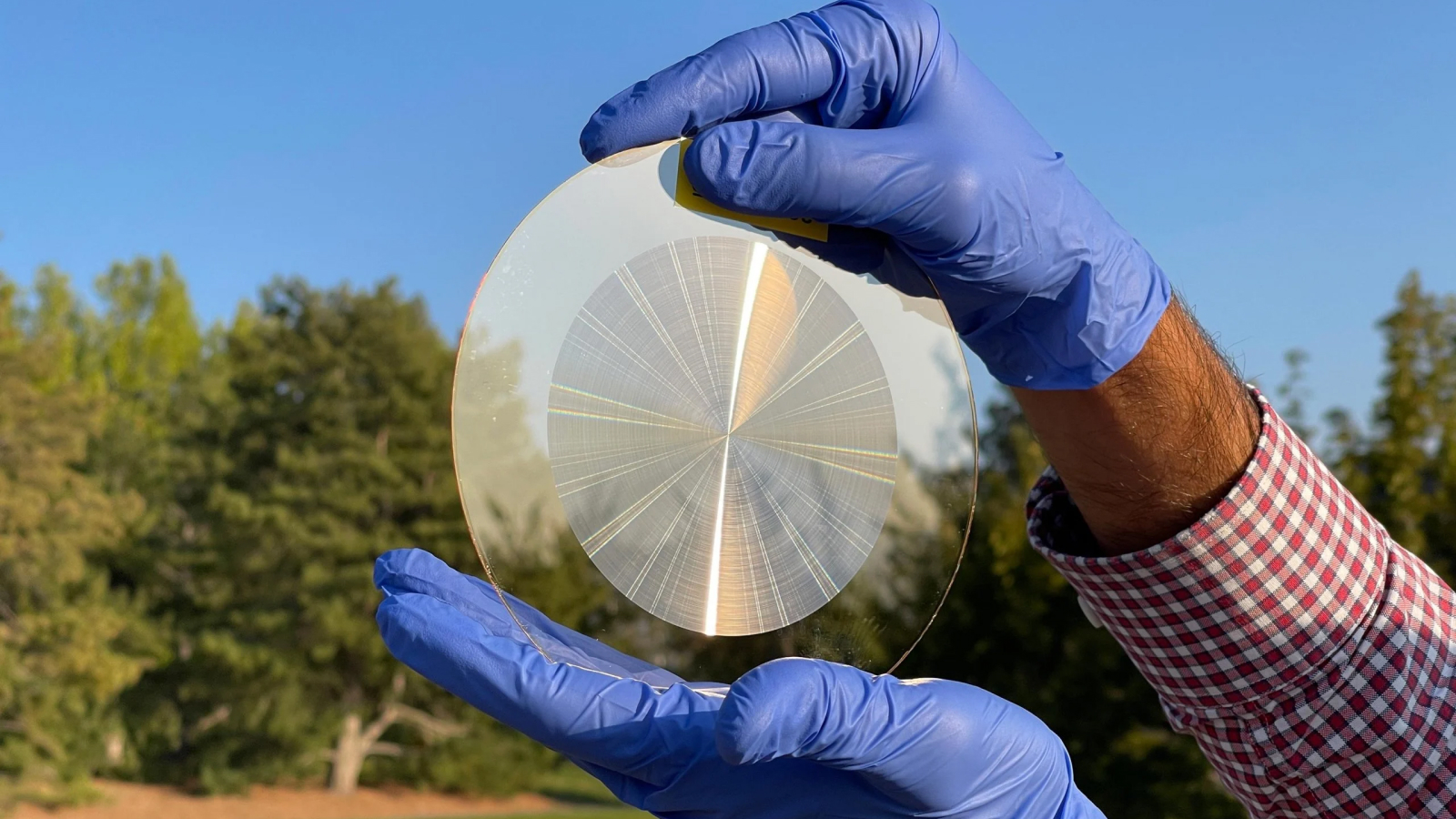

scientist have organise a fresh approach path to make prominent , pellucid screen at low price — and they trust it could direct to more low-priced gauze-like television receiver in the dear future .

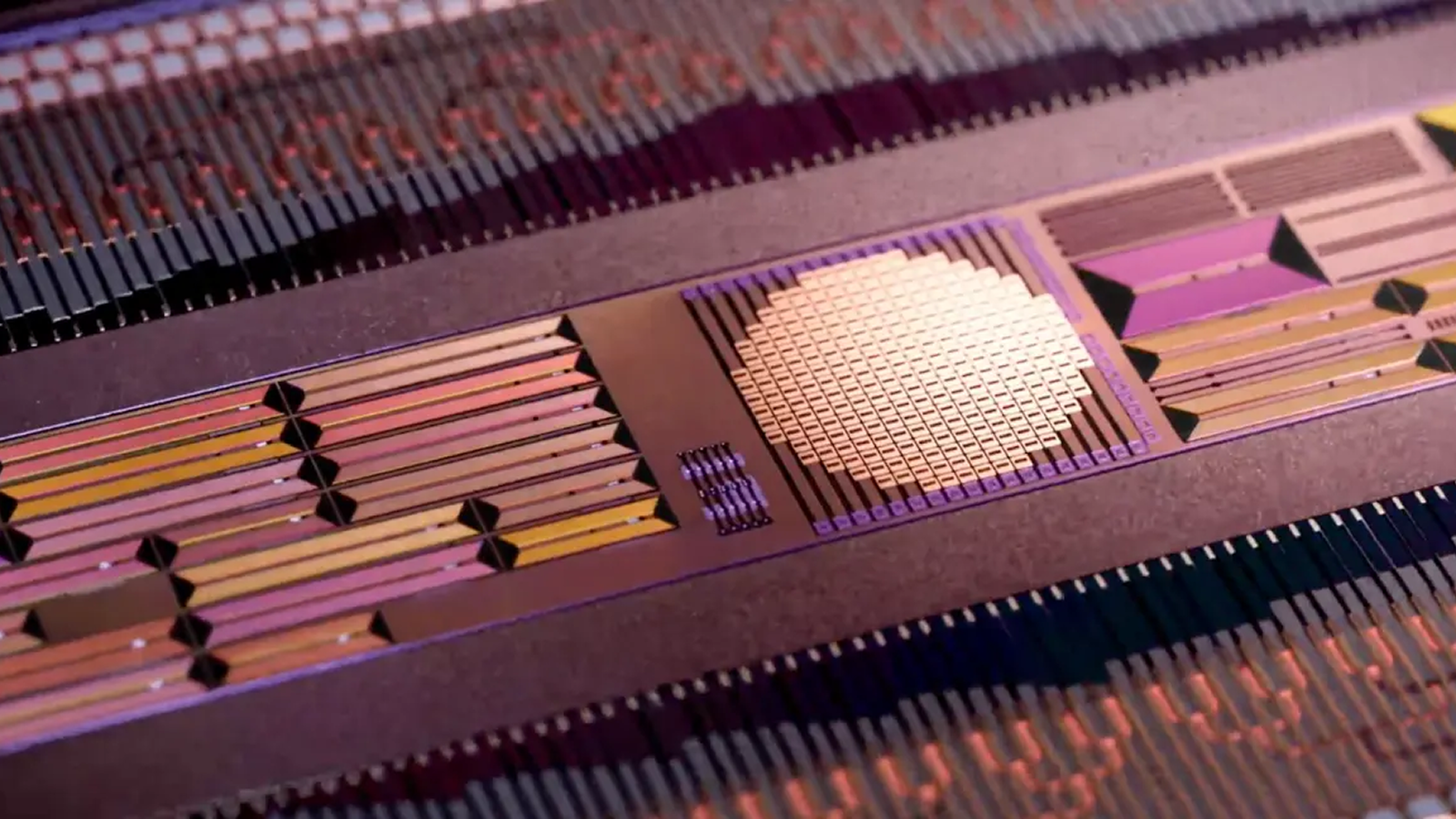

Using a young form of film material , scientist have developed a 100 - inch nano transparent screen ( NTS ) that is as thin as a human hair and capable of shew detailed mental image with a high point of colour and light uncloudedness .

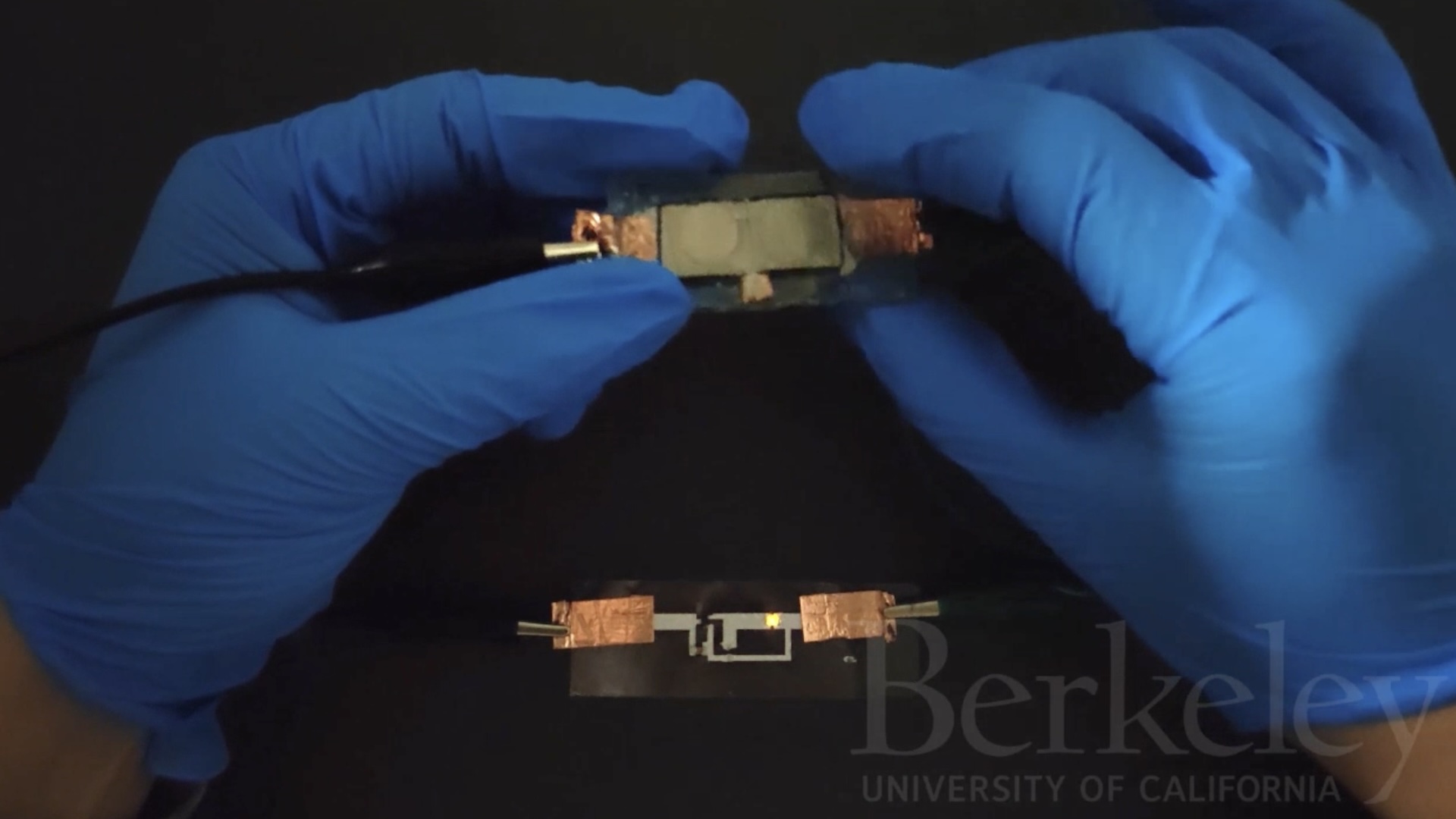

The 100-inch nano transparent screen (NTS) is made in a roll-to-roll process in which a sheet of film is treated with tiny particles of titanium dioxide.

In addition to its light and flexible coming into court , the control board ’s transparency can be adjust — with the screen adequate to of prove the most detail when at its most opaque . It is also highly musing to place Christ Within , bring forth unmortgaged images when hit with a beam from a powerful projector , and has a lossless 170 - degree take in angle on either side .

investigator at the Korea Institute of Machinery and Materials ( KIMM ) , in collaboration with the secret company Meta2People have also start to commercialize the NTS , which is made in a roll - to - roster process in which a sheet of plastic film is treated with tiny particles of titanium dioxide .

These nanoparticles give the NTS its durability and improve the optic quality of the film , the scientists said , intend images projected onto it remain clear . The film is also layer with a form of quartz polymer know as a polymer dispersed liquid crystal ( PDLC ) moving picture . By put on an electrical field to the crystal , the PDLC can be made more or less transparent — allowing the silver screen to become more unintelligible when users desire to see more point on the filmdom .

The 100-inch nano transparent screen (NTS) is as thin as a human hair.

Purchasing conventional transparent OLED covert would cost KRW 100 million ( just about $ 72,000 ) , the research worker added . But their new instrument panel would be just one - ten percent of that shape . That ’s because the manufacturing process is easy to replicate due to its comparative simplicity , they claimed . It can already be replicated in existing manufacturing condition and is highly repellent to extreme heat and cold — meaning it can be used indoors and outdoors .

— diminutive , pellucid microchip could transform your smartphone into a professional - grade camera

— calculator inspired by Japanese fine art of composition - cutting has no electronics and stores data in tiny cubes

— New design transforms any smartphone or television display into a holographic projector

" The engineering for cook up NTSs is a cutting - bound , innovative engineering created through the combination of nanomaterials and nanomanufacturing applied science with subsist IT technologies , " say Jun - Ho Jeong , principal researcher at KIMM in astatement . " go forward , we will focus on research and development to continuously meliorate the quality of NTSs and start the vulgarization of see-through screenland . "

The research worker have only start on their journey to commercialize the NTS screen , but they have patented their engineering science in collaboration with scientist at Meta2People .