When you buy through links on our site , we may earn an affiliate commission . Here ’s how it work .

Paper is a ubiquitous part of casual life , but how is it made , and where did it originate ?

Ancient Egyptians madean early version of flora - establish paperusing papyrus — which is where the word " paper " comes from . They transfer fibers from the stem of the Egyptian paper reed works ( Cyperus papyrus ) , a marsh Walter Reed topped with flowers that can develop up to 16.4 feet ( 5 meters ) tall . Ancient Egyptians layered the fibers next to each other , and then dampened and pressed the canvas . Papyrus sheet were used to save letters , platter administrative documents , and write chronicle and religious texts .

Paper is made from wood by stripping the bark from trees then chipping it and turning into a pulp.

Over 2,000 years ago the great unwashed inChinainvented a process closer to papermaking as we know it , boil hemp plantsinto a pulp , then forming the pulp into a sheet and drying it . This type of papermaking traveled west to Baghdad about 1,400 years ago , where the city becamefamed for paper productionand began to sell newspaper and books .

Paper then reached Europe , where medieval Europeans made paper bycutting up linen paper and cotton plant rags , soaking them , and treat them . The first ragtime - newspaper mill number to the North American European colony in 1690 .

Over prison term newspaper mills faced shortages of rags , so people turned to a inexpensive and more abundant textile — wood .

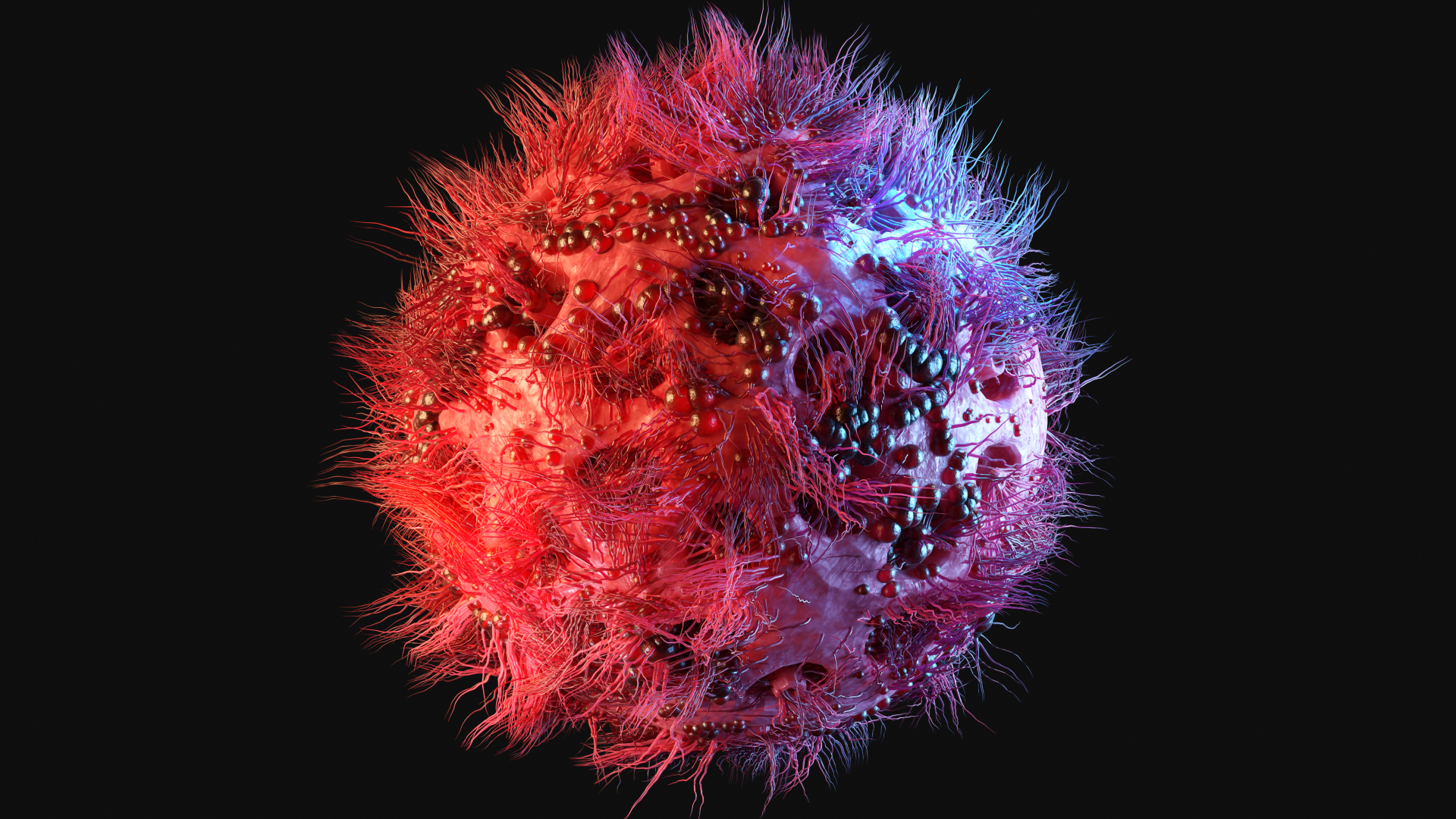

Paper production can release pollutants into the environment, and scientists are now working to make the industry more sustainable.

Thefirst U.S. newspaperprinted on paper made from trees was an variant of the Boston Weekly Journal published in January 1863 .

Today , the process of making paperbegins with loggers cutting Tree and work them to report mills : eithersoftwood treeslike pine , spruce , and fir , or hardwood tree like oak , birch rod , and eucalypt . political machine slice off the bark , the privileged wood is cut off into small patch , and these pieces are boil into a goopy pulp . How much and how exactly the flesh is fake depends on the intend properties of the final product : the pulp is cooked and processed more if the resulting newspaper need to be firmer or have less opacity .

Cell paries of tree cells are a cardinal component to the mush : cadre wall of all plants containcellulose , known to chemists as a one-dimensional polysaccharide . These molecules are highly durable and compromising . Cellulose fibers also steep water well , while remaining strong . These timbre make them idealistic for creating paper .

Paper production can release pollutants into the environment, and scientists are now working to make the industry more sustainable.

Related : The erstwhile tree in the world ( and the 7 runner - ups )

After being cooked , the pulp is suspend in water , filtered onto a interweave screen to form a sheet of paper , pressed flat to get rid of lumps and water system , and dry . In the past this whole process was completed one rag at a fourth dimension , but it has now beenmechanizedto occur much faster .

Different type and tier of theme depend on the character of pulp magazine used , how much the pulp has been beaten or elaborate , what other material have been added to the wood pulp , dimension when forming the sheets like thickness , and chemical substance discussion added at the final stage of the process , according toEricka Redmond , chemist and paper railroad engineer at the State University of New York School of Environmental Science and Forestry .

" The operation [ for making newspaper publisher ] has been very established , " Redmond say . .

But the newspaper publisher diligence is not environmentally friendly . effluent from the process can free pollutants thatharm ecosystem and human wellness . So most paper institution concentrate on finding fresh uses for residue from paper yield , to make the process more sustainable , reduce the use of goods and services of chemicals , and reduce pollutants .

Many newspaper mill can generate their own vigor and be self - sufficient , Redmond say . Steam generated from boiling Sir Henry Joseph Wood pulp can power the factory , and chemic residue from the papermaking process can be recycle .

— Ancient Greek ' calculator ' came with a user usher

— Do Tree exist ( scientifically speaking ) ?

— Why does cotton shrink ?

newspaper technologist are conducting research to make the process more self - maintain , and to sympathize how to plug chemical substance residues back into the process so the manufacture causes less befoulment .

As the world becomes increasingly digital , paper is used less for composition and impression — but the requirement for cardboard and paper promotion is still high , Redmond told Live Science . So many parcel are now delivered in composition board boxes , and market memory have switched from charge plate to paper bags , so the paper industry is work on amend these products .

One goal is to make recycled paper promotion unattackable and more long-lived . Redmond focalise on sustainable coatings for food publicity — for example , non - pliant , compostable coatings for the inside of paper cup that make a roadblock so your report cup wo n’t get marshy or leak .