When you purchase through data link on our site , we may pull in an affiliate commission . Here ’s how it works .

Electric vehicles could buck 500 % quicker in inhuman weather condition thanks to a new manufacturing process , research suggests .

In a new report release March 17 in the journalJoule , scientists explained how they could markedly improve Lithium - ion stamp battery charging pace in temperature as low-pitched as 14 degrees Fahrenheit ( minus 10 degree Anders Celsius ) by tweaking the structural intention of the battery and modify the chemic reactions that come during charging .

Cold temperatures limit charging rates and reduce overall energy efficiency due to the chemical processes at play during charging.

The researchers were able to " at the same time achieve extreme degenerate charging at low-down temperature , without sacrifice the energy density of the atomic number 3 - ion battery,“Neil Dasgupta , study author and associate professor of mechanically skillful engine room and materials skill at the University of -Michigan , said in astatement .

dusty temperatures fix send rates and reduce overall energy efficiency due to the chemical substance process at turn during charging .

Batteries work by impress lithium ions between two electrode plates within a fluent electrolyte result . This appendage is efficient in warm temperatures , but in colder conditions , the electrolyte fluid thickens , reducing electrical current and thereby extending blame prison term .

Related : Future electric cars could go more than 600 miles on a single commission thanks to battery - boosting gel

It ’s an issue manufacturing business have address in several ways , including increasing the thickness of the electrodes used in battery cells or by modify the social organisation of the battery itself . But these steps have further exacerbate the problem . A 2023 study on lithium - ion battery efficiency show alterations to the composition of electrolytesimpeded fast - charging capacity , for example .

Researchers create new ‘pathways’ for ions

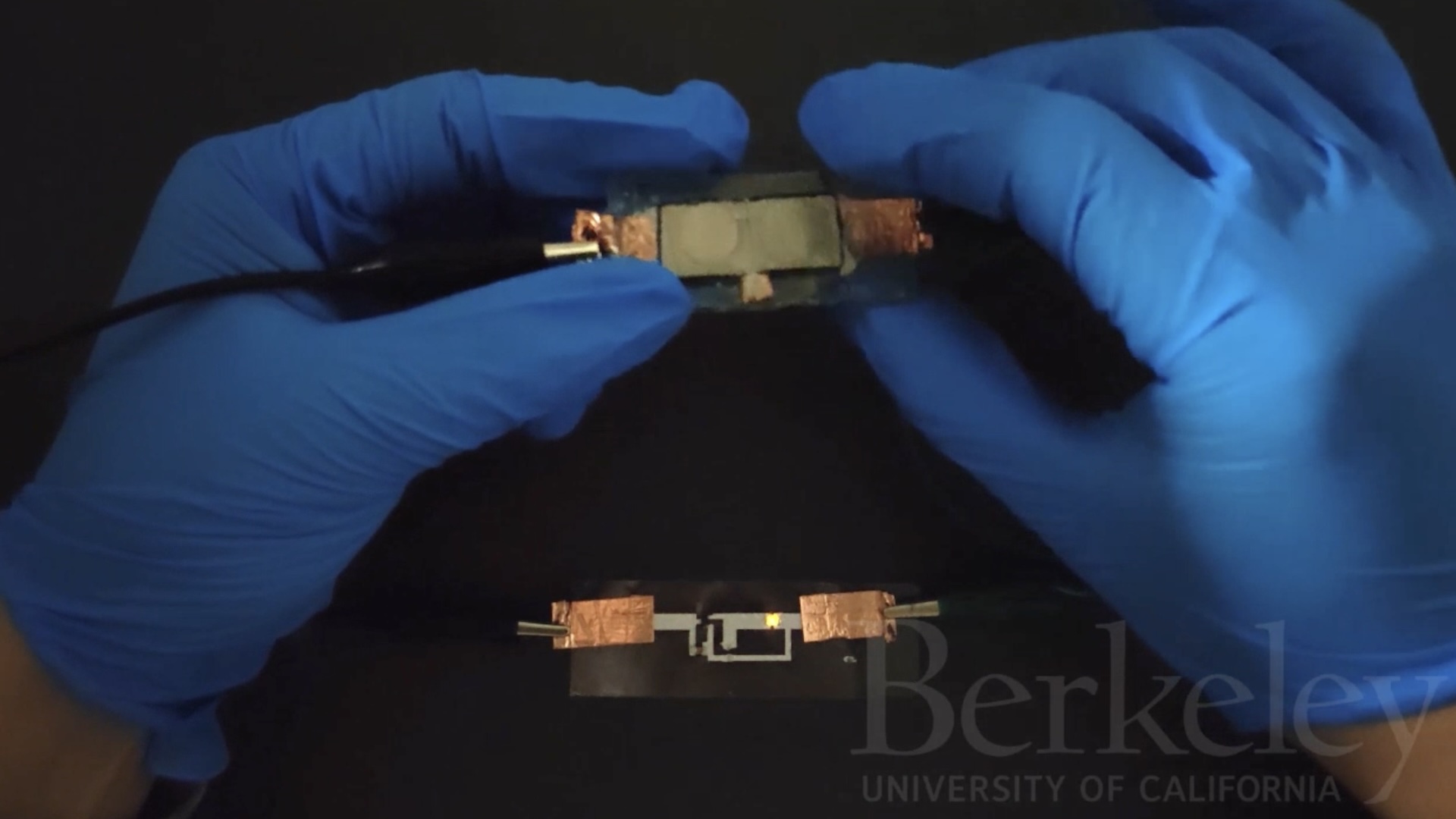

In aprevious studypublished in 2020 , the investigator created what they described as new " pathways " in the anode — the electrode that receive lithium ions during charging and sends electron to the cathode at the opposite end .

To create these pathways , the researchers used lasers to jab holes in the anode ’s graphite layers , which enabled lithium ions to move faster , in turn meaning they could plant themselves more rapidly within the electrode .

This earlier project sped up charging times , but in cold weather condition conditions , it created a buildup of Li on the anode . This " metal plating , " forestall the electrode from react with the electrolyte fluid .

" That plating keep the intact electrode from being charged , once again reduce the battery ’s energy capacity , " study co - authorManoj Jangid , a senior inquiry beau at the University of Michigan , told Live Science .

To prevent this level from forming , in the new study they coat the bombardment with a 20 nanometre - thick fabric made from Li borate - carbonate . old inquiry in upstanding - country barrage show that this materialimproved the efficiency of ion delivery .

— China ’s superfast charging technology is double as fast as Tesla ’s — to the full recharging electron volt in just 6 minutes

— Honda promises solid - state batteries that could double EV kitchen stove to 620 geographical mile by 2030

— World ’s 1st Si anode EV battery will let you drive up to 186 miles after just 5 arcminute of charging

In this representative , the coating , combined with the pathways technique delivered a 500 % increment in charging efficiency in sub - zero temperature , the researchers say . Batteries modified using these techniques also hold 97 % of their capacity , even when fast - charged up to 100 times in subfreezing temperature .

While the study was limited in scope , Dasgupta said the changes are well-off to implement at the fabrication degree and could have wide - ranging implications .

" We envision this approaching as something that EV stamp battery manufacturers could adopt without major changes to existing factories , " Dasgupta said .

You must confirm your public display name before commenting

Please logout and then login again , you will then be prompt to go in your display name .