Topics

in style

AI

Amazon

Image Credits:Diagon / Diagon co-founders Shri Muthu and Will Drewery

Apps

Biotech & Health

mood

Image Credits:Diagon / Diagon co-founders Shri Muthu and Will Drewery

Cloud Computing

Commerce

Crypto

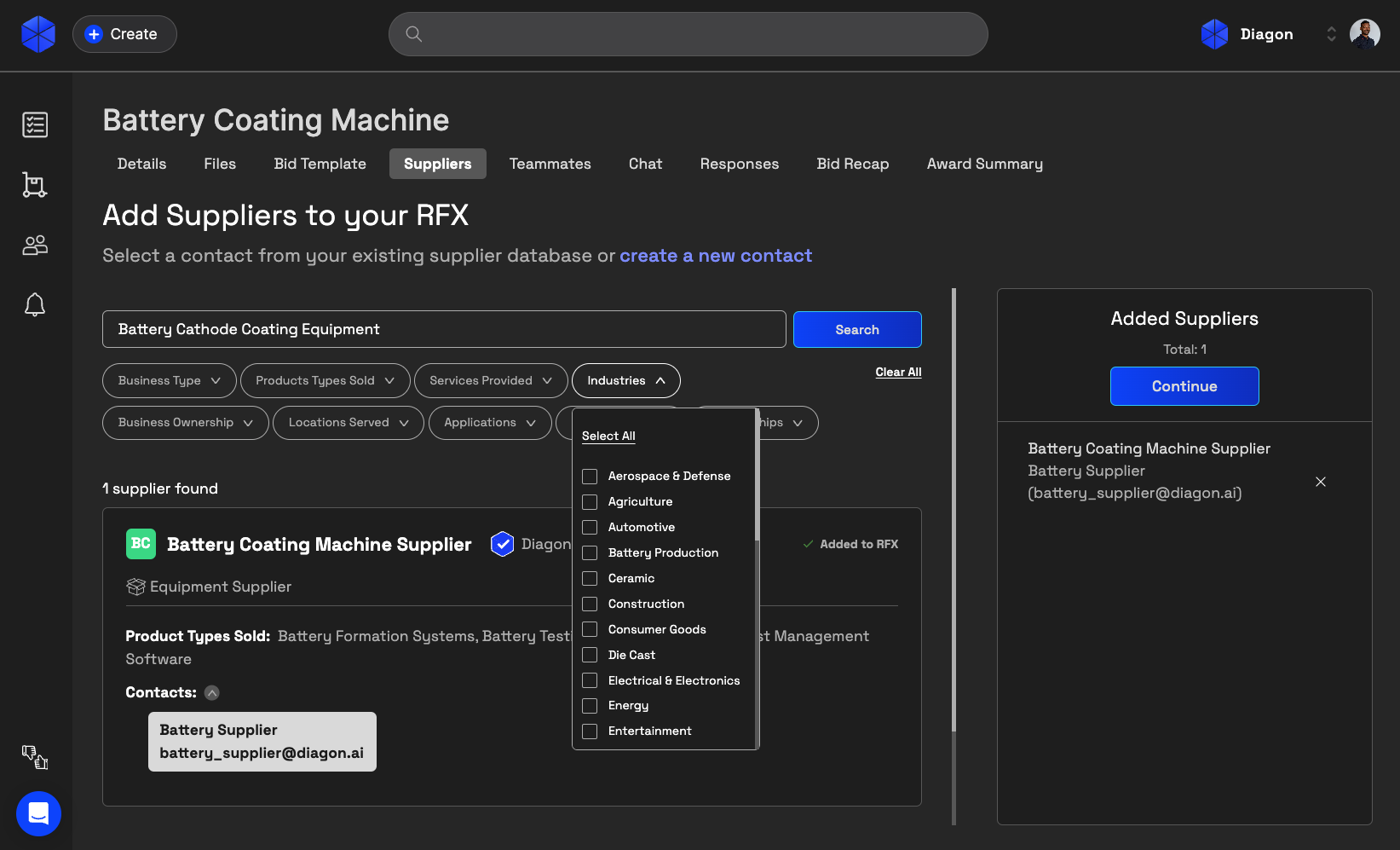

Diagon dashboard shows supplier discovery feature for battery equipment.Image Credits:Diagon

Enterprise

EVs

Fintech

fund raise

Gadgets

Gaming

Government & Policy

Hardware

Layoffs

Media & Entertainment

Meta

Microsoft

Privacy

Robotics

certificate

Social

outer space

Startups

TikTok

Transportation

speculation

More from TechCrunch

Events

Startup Battlefield

StrictlyVC

Podcasts

TV

Partner Content

TechCrunch Brand Studio

Crunchboard

Contact Us

It ’s not everyday that you get to sharpen your skills with Elon Musk as your boss . It was while sourcing manufacturing equipment for Tesla factory that Will Drewery drew inspiration forDiagon , a inauguration that helps manufacturer procure equipment .

“ Big project companies are building now , like battery fabrication , need very specific types of process equipment and automation equipment to ramp up a mill and automate , ” co - founding father and CEO Drewery told TechCrunch . “ I ’d been hearing and seeing the trends toward nearshoring and reshoring of American manufacturing . As a provision chain director , I ’ve been taking a decisive eye at how that ’s actually going to find . masses intuitively understand that they want to source batteries for the cars they ’re earn in the U.S. or near the U.S. , but they have no musical theme if that content does n’t exist anywhere , then there ’s no fashion you ’re going to discover a dependant provider or have the good substructure to make those products . ”

In January 2023 , he start Diagon with former Snackpass vice prexy of engineering Shri Muthu so that companies of all sizes could tap into his expertness of receive sourced equipment for Tesla ’s electrical vehicle and stamp battery facilities . company in fields like self-propelling and aerospace can key dependant suppliers from Diagon ’s meshwork of equipment suppliers , scheme integrators and serving providers , then leverage a toolkit to manage those complex projection .

Diagon also uses artificial intelligence to get answers to questions like , what type of base will companies need to become a dependant iron - based battery provider in the U.S. ? , or what types of things will the company require in decree to make those products ?

East Coast origins

The journeying to Diagon for Drewery , who pass most of his career as an equipment buyer , started in Pittsburgh . When Drewery was maturate up , his father and uncles worked in the blade industriousness . It was a “ great way to make a living for a farsighted time ” until globalization shifted fabrication shopping center elsewhere , he enounce .

“ It impacted me to see not only the diligence , but the businesses that stomach it , being impress , ” Drewery said . “ I had this intuition that there was a much bigger import to being capable to fabricate to confirm a local economy . ”

A few years later , Drewery fall in PwC as a consultant before joining the U.S. Department of Defense as a declarer . This positioning took him to Baghdad , where one of his projects was to help troupe secure machinery and equipment to reconstruct facility damaged during the state of war .

Join us at TechCrunch Sessions: AI

Exhibit at TechCrunch Sessions: AI

After graduating from business enterprise school in 2012 , Drewery move to the Bay Area , where a Quaker tell apart him about Tesla . The company had just bought an old manufactory in Fremont and was stripping out the old equipment and ask someone to assist source young equipment to make the Tesla S , X and 3 models .

His champion brought a Tesla to a party Drewery was at , and after strike joy ride up and down the motorway , Drewery recall opine , “ I do n’t know what this company is doing , but I ’ll do anything to solve there . ”

A glimpse inside Tesla ’s super closelipped Gigafactory

Working for Elon

Tesla , Drewery learned , was similar to most organization when it came to the supply mountain chain .

“ They ’re not really focus on buying the infrastructure for the factory — that tend to be left to engineers and other people within the establishment , ” Drewery said . “ When I derive in , I was the first individual , really the first formal vendee , the ship’s company ever hired to source this type of machinery and equipment . Up until then , the engineers and shop managers were source their own stuff . ”

It was Drewery ’s job to source all the industrial robots , the metal mechanical press and plastic molding machine . That grew into source for the entire scope of Tesla ’s manufacturing footprint , both inFremontandBuffalo , New York , and also in thegigafactory in Reno , Nevada .

It was quite an education , Drewery recalls . It was hard to describe provider and where they were located . How to pay for those materials , and how to actually source everything . This is because a lot of the equipment did n’t fall into the norm of affair that most provision chain managers corrupt , he said .

Drewery ended up getting a crash - path education in supply Ernst Boris Chain . He find out which suppliers made which case of equipment , all the pricing , principal clock time and other negotiation .

Also during this clock time , Drewery gained experience building out a moderately substantial squad to tackle all of that . He grew his team to 30 people that was managing about $ 700 million a year in Washington expending , Drewery said . During his clock time at Tesla , that was about $ 3.5 billion .

“ One of the coolest jobs — hands down — that I ’ve ever had , and I was awestruck at how few tools there were to help me do that job , ” he said .

And what was it like working with Elon Musk ? “ I ’ve never determine more than I learn in that role , but it was the hardest thing that I ’ve ever done . Up until starting this company , I ’d say that , ” Drewery said .

Here ’s a piddling sampling of what that involved . Trade show are the top stead to find company that make these case of equipment . However , how do you take off a day of employment to attend league when your foreman is Elon Musk ?

“ A lot of times I would have to do it under the microwave radar , ” Drewery said .

Putting those skills to work for others

Drewery worked at Tesla between 2013 and 2018 . During that metre , he also had to make out delivery of all of that equipment and the examination and instalment of it . This could take anywhere from a few calendar month to a few years , he say . Drewery had a satisfying squad working with him but thought much about company that do n’t have the team or prick to do the same .

“ This is why I felt the market demand a Diagon , ” Drewery said .

Diagon launch its equipment sourcing and procurement political platform in November 2023 after being a part of startup accelerator Techstars . It grew to six employees and a half - dozen customers , let in Mitra Chem , Zeno Power and Mighty Buildings .

The society will deploy its software platform as a pilot program program with its professional services client first and do a broader dismissal this summer , Drewery tell .

The companionship also late raise $ 5.1 million that include a former $ 800,000 SAFE ( simple agreement for future fairness ) round . The Westly Group led the round of golf and was joined by Valia Ventures , Techstars , Foster Ventures , Foxe Capital , Anthemis and ReFashiond Ventures .

The funding founder Diagon a good rail for the next two days and will start the company to actively engage , including for a head of ware and go - to - market .

“ Now we are developing puppet that help client find supplier better or help them read and summarize quotes better , ” Drewery said . “ We will pluck those out as we develop them . We ’ve also got some runway to acquire Modern customers and build more of the intersection until we raise our Series A , which we have n’t embark on fundraising for yet . ”

Northvolt ’s $ 5B debt deal should be a wake - up call for the US stamp battery manufacture