When you buy through links on our site , we may earn an affiliate mission . Here ’s how it works .

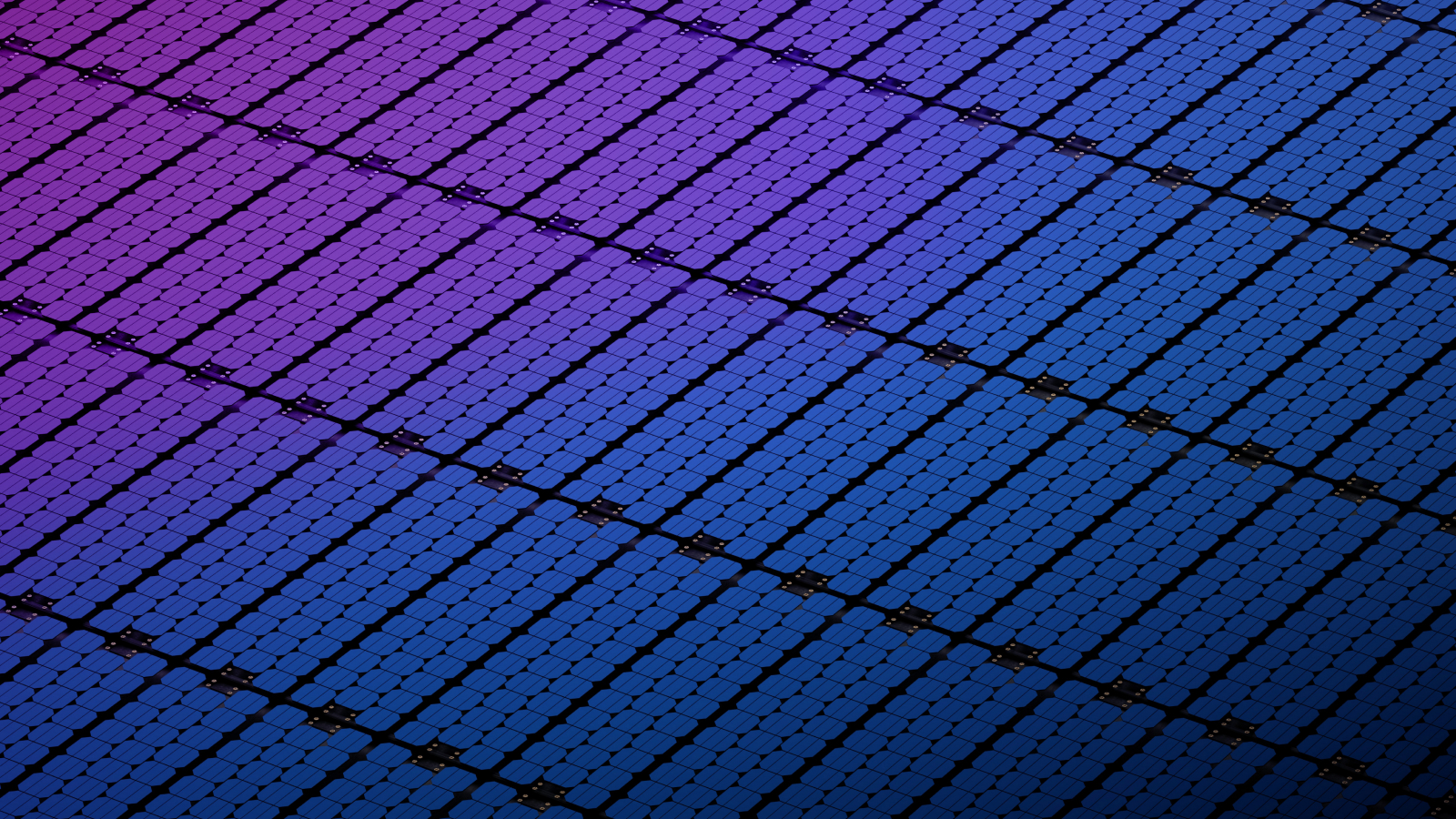

supervene upon gadgets like smartphones or laptop computer just because the shelling stops agree commission can be a real worry . But new research outline a way to give commonlithium - ion batteriesa much longer lifespan — starting with their very first charge wheel .

lodge Li - ion battery — which mightiness most personal electronics andelectric vehicle ( EVs ) — at high temperatures or current before they shoot the ledge could unfold their average lifespans by 50 % , researchers said in a new subject published Aug. 29 in the journalJoule .

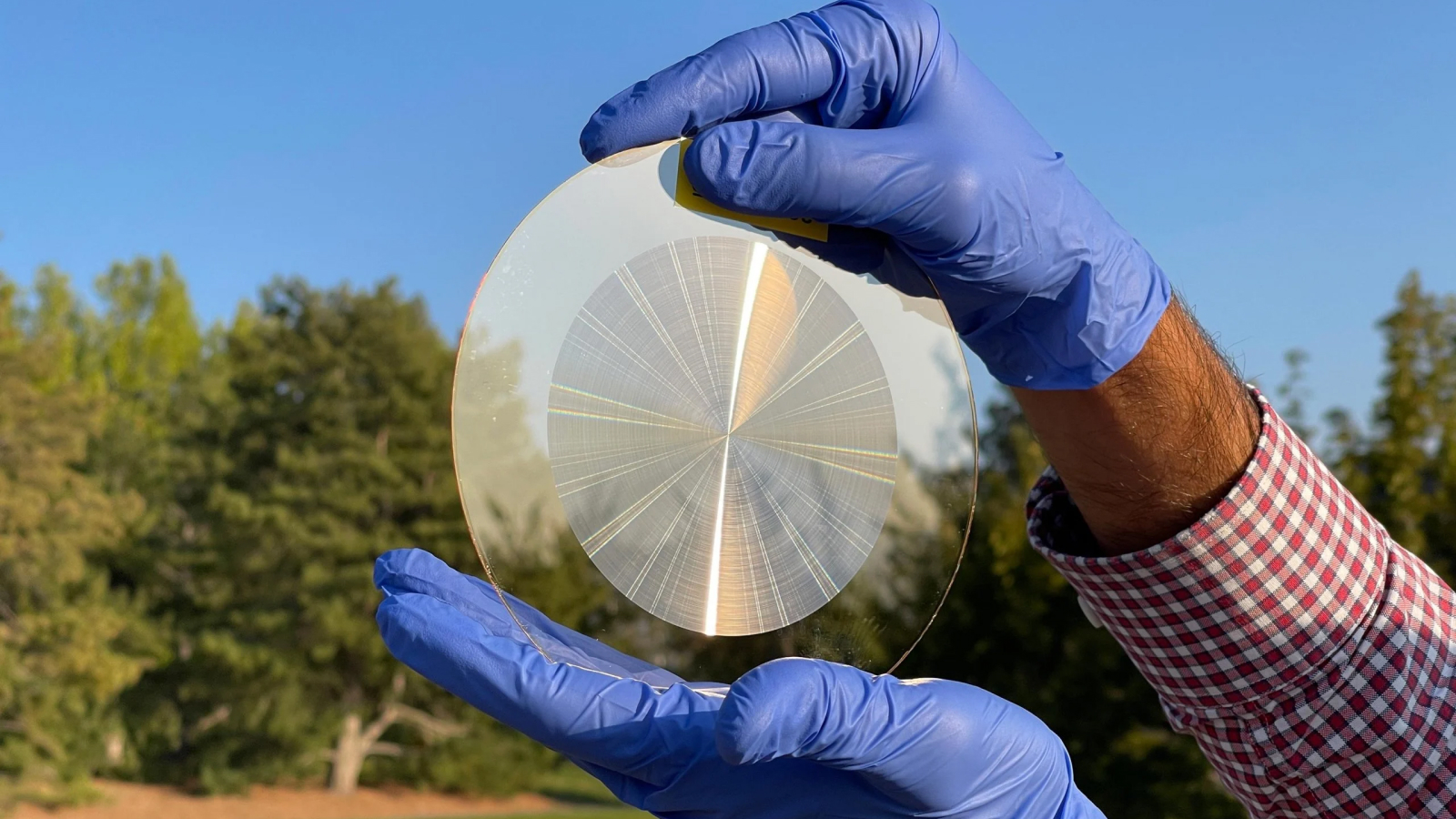

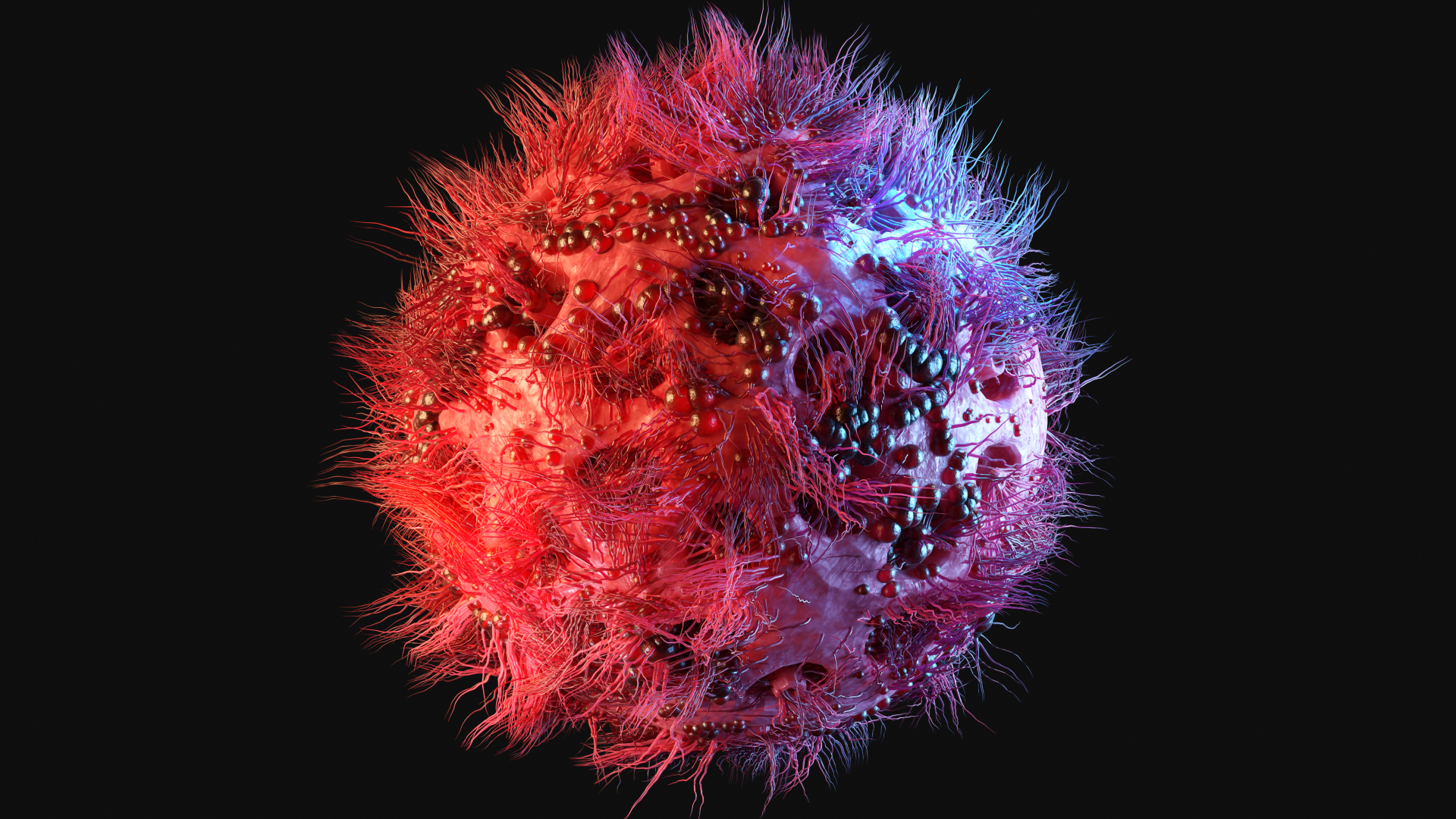

Building a larger solid electrolyte interphase (SEI), solid lithium that encases the negative electrode, reduces the risk long-term side reactions and extends overall lifespan.

The upshot " demonstrate a generalizable approach for understanding and optimizing this essential step in shelling manufacturing , " say bailiwick coauthorSteven Torrisi , a senior enquiry scientist at the Toyota Research Institute in California , in astatement .

A typical Li - ion barrage has a positive and a minus electrode in an electrolyte result check Li ion . When you charge the battery , lithium ion move into the negative electrode . Then , when you use the battery and expend its charge , the atomic number 3 ions move out of the negative electrode and into the electropositive one . The back - and - Forth River flow of ion facilitates the electric current that powers a machine .

Related : Charging future EVs could take seconds with novel sodium - ion battery

A brand - new Li - ion barrage fire is all discharged — the confirming electrode is full of Li , and the negative electrode has plenty of distance for lithium ions to flow into . But on the first tutelage , some of the atomic number 3 in the battery gets stuck on the surface of the negative electrode . The trapped lithium , along with other ingredient of the electrolyte result , becomes part of a layer called the solid electrolyte interphase ( SEI ) . This SEI encases the damaging electrode , protecting it from side reaction that cause further loss of lithium and so reduce the battery ’s lifespan .

commonly , manufacturers first charge the electric battery slowly to build up a static SEI . But that is n’t always the most monetary value - good glide slope — andrecentstudiesshow that charging the stamp battery cursorily does n’t of necessity have a negative wallop on the barrage ’s life sentence . What ’s more , several other parameter can touch on the SEI , so it ’s not easy to optimize the first commission for the best battery performance .

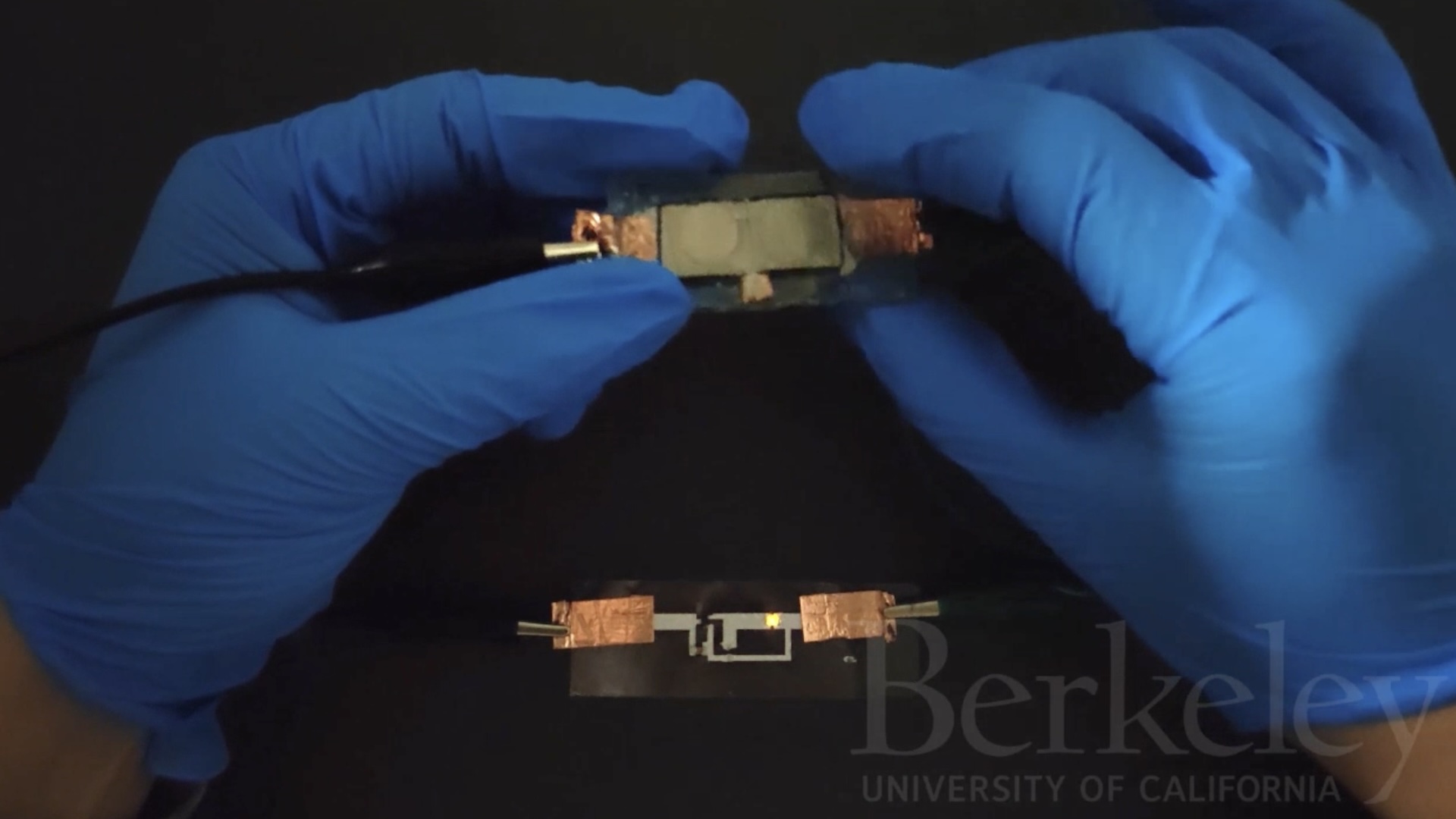

In the new study , researchers used machine learning to pick out the parameter that have the strongest effect on the SEI . Two factors — the current and temperature during the first charge — grab their attention .

— World ’s biggest battery derive to Maine — and it could put in 130 million times more energy than your laptop

— World ’s fastest charger can fully power up your smartphone in under 5 minutes

— MIT scientist construct hairsbreadth - sized shelling that can power cell - sized robots

blame the battery over about 20 minutes , rather of the common 10 hour or so , hold out the battery ’s overall lifespan by about 50 % . More Li get stick by in the SEI on the first charge , but that limits the possibility of future side reactions that can abridge the shelling ’s life on subsequent cycles .

Raising the temperature from room temperature to 131 degree Fahrenheit ( 55 degrees Celsius ) had a similar effect , ameliorate the battery ’s lifespan by an average of 57 % . That improvement likely comes from changes in the SEI composition that make it more full-bodied , the researchers said . However , the technique did n’t synergize : charge the cell both quickly and at in high spirits temperature did n’t improve battery public presentation .

" We did n’t just need to identify the best recipe for wee a unspoilt stamp battery ; we desire to interpret how and why it works , " tell study coauthorWill Chueh , a materials scientist at Stanford University , in the financial statement . " This reason is important for finding the best balance between battery performance and manufacturing efficiency . "

The new scheme could make batteries gaudy too , Chueh said . “ This is an excellent example of how [ the Stanford Linear Accelerator Center ] is doing manufacture science to make critical technologies for the energy transition more affordable , ” he remark . “ We ’re figure out a real challenge that industry is front . ”